Adventure bikes rack up hard miles. The shocks on these bikes are especially prone to wear and deterioration by how they are used and their construction. We stopped in at Cogent Dynamics and learned about shock service and improvement from owner and suspension specialist Rick Tannenbaum.

Our guinea pig is the KYB shock on the Suzuki DR650. The lessons learned here apply to many other shocks that might not be considered serviceable at first glance. Looking in the Suzuki repair manual you won’t find any instructions for servicing this critical component. It can be serviced if you treat it like the quality shock absorber it is and have some background knowledge on shock absorber construction.

The shock disassembly starts out in a typical manner with spring removal. The damper can now be inspected free of the spring. The damper shaft should move smoothly. If the movement is too light or inconsistent, the bladder may have failed allowing the gas to mix with the oil inside the shock body.

Vent the gas pressure from the bladder and remove it. If the bladder cap won’t budge the gas may have leaked into the shock body. If this is the case it needs must be vented by very slowly removing the damping adjuster from shock body.

Remove the seal head dust cover, circlip and free the shock shaft assembly from the body. Dispose of the old shock oil and clean the components thoroughly.

Remove the seal head dust cover, circlip and free the shock shaft assembly from the body. Dispose of the old shock oil and clean the components thoroughly.

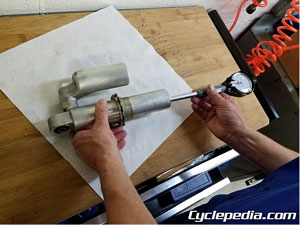

The shock body of the DR650, like many other stock shocks, is made of raw aluminum. It wears very quickly. Cogent Dynamics offers a hard anodizing service to greatly improve the wear resistance. Inspect the body for signs of damage and measure its diameter front-to-rear and side-to-side at multiple levels. Replace the shock body if it is more than 0.5 mm out of round. Use a hone to smooth out any wear or burrs from the inside of the shock body.

So far all of this is pretty normal for a shock rebuild. This is where that starts to change. This shock isn’t designed with service in mind like a motocross shock. It is a bit more difficult to disassemble from this point on. This type of work can be sent off to a qualified suspension company like Cogent Dynamics if necessary.

A high performance shock that is intended for service will have a valve nut that is lightly peened to the shock shaft. This can be freed up with a hand file. Shocks like the DR650’s are a bit more difficult. Avoid taking off too much material and wiping out the threads of the shock shaft is using a grinder. The more precise way of removing the nut is to use a lathe.

Use the lathe to turn down the peened nut until it reaches the root diameter of the shock shaft thread. Extreme care is needed to avoid removing too much material. The shock shaft can then be disassembled for seal head and valve component replacement. Use a new nut with red Loctite on assembly.

The compression adjuster also takes special care as it is peened to the shock body. Carefully drill out the body where it is peened. If the threads are significantly damage the components may be ruined.

When the shock shaft and bladder have been installed it is time to fill the oil. Cogent Dynamics uses a vacuum pump to create a vacuum inside the shock and draw the oil into the shock. They then apply vacuum again to draw any air out of the oil. This is much quicker and produces a better result than bleeding by hand. Top off the oil as needed and reinstall the damping adjuster with red Loctite.

When the shock shaft and bladder have been installed it is time to fill the oil. Cogent Dynamics uses a vacuum pump to create a vacuum inside the shock and draw the oil into the shock. They then apply vacuum again to draw any air out of the oil. This is much quicker and produces a better result than bleeding by hand. Top off the oil as needed and reinstall the damping adjuster with red Loctite.

Don’t give up on the stock shock. It can probably be rebuilt with the help of the aftermarket parts for less than the cost new stock. It can be enhanced and re-valved as well to match the needs of an exacting rider.

* Courtesy Will Graham | Technical Editor | Cyclepedia Press LLC