- Home

- Sale!

- Shop

- Featured

- Featured Products

-

DDC (Drop in Damper Cartridge) for the Yamaha TW200

0 out of 5$232.95

DDC (Drop in Damper Cartridge) for the Yamaha TW200

0 out of 5$232.95 -

Complete DDC kit for the Yamaha TW200

0 out of 5$379.95

Complete DDC kit for the Yamaha TW200

0 out of 5$379.95 -

Kawasaki KLR650 Adjustable Fork Caps Gen One 1987-2007

0 out of 5$208.95

Kawasaki KLR650 Adjustable Fork Caps Gen One 1987-2007

0 out of 5$208.95

-

- Featured Products

- About

- Service

- Bikes

- Resources

- Contact

KLR650 DDC Installation Instructions 2008-Current and New Edition 2014-Current

Thank you for purchasing your Cogent Dynamics Drop in Damper Cartridge (DDC). This easy to install damping solution will update your KLR650 forks to new levels of performance. Each Cogent DDC kit has been engineered to enhance the performance of your bike. The Cogent Dynamics DDC modification will improve both compression and rebound damping characteristics of the KLR650 forks, providing outstanding feel and traction.

These instructions assume familiarity with damper rod type fork internals and the necessary technical tools and ability. Installation of your new DDC requires that your forks are in good condition and have the proper type and level of fork oil. Your Cogent DDC was calibrated to use Golden Spectro Cartridge Fork Fluid 85/150 (5 wt.) which is a synthetic blend suspension fluid made in the USA for cartridge type forks. An approximate volume of 600 ML per fork leg will be needed to fill the tube to the correct level. We also recommend that you incorporate the appropriate straight rate springs for your application (The DDC set, springs and pre- engineered spacers are included in the Cogent Fork Performance Kit). No drilling, welding or other modifications are needed to complete the installation.

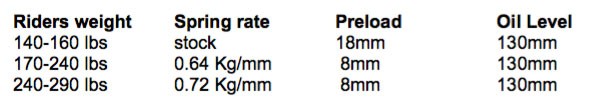

Spring recommendations for the Cogent Dynamics DDC

Installation Procedure: (We highly recommend you perform a ‘dry run’ to familiarize yourself with the installation procedure before you complete the install with oil.)

- Elevate motorcycle and remove front wheel.

- Loosen top triple clamp bolts.

- Loosen fork caps while fork tubes are still held by the lower triple clamp.

- Remove forks from motorcycle.

- Remove fork cap, preload spacers, washer and main spring from each tube.

- Remove fork oil by inverting fork over a suitable container and pump forks until nomore oil is in the fork. Let fork stand upside down for 15 minutes to thoroughlydrain all oil.

- . Add new fork oil (Spectro 5 wt.) and bleed fork by slowly the pumping the fork tube up and down until air bubbles quit coming up.

- Ensure oil level is set by fully compressing fork and measuring from the top edge ofthe steel fork tube to the oil level (130mm in most cases).

- Carefully lower the DDC into the fork, orienting the smaller O.D. locating ring andnylock nut downward. Ensure that the DDC is fully seated into the damper rod head.

- 10.Install spring with the OEM washer at the top. Use the Cogent spacer or cut a spacer to provide correct spring preload (8mm in most cases).

- 11. Extend the fork and measure from the top of the spacer to the top edge of the fork tube and assure the fork is not recompressed during this step as it can unseat the DDC. A measurement of approximately 9-11mm assures that the DDC is seated and the correct length spacer is installed. This assumes you are using a Cogent approved spring and are not compressing the top out spring.

- Install fork cap and reinstall forks into your bike.

- Install front wheel. Always cycle front suspension up and down a few times whilewhile holding bike stationary with front brake before tightening axle pinch bolts.This will assist in aligning front suspension and assure front brake operation.

- Ride and enjoy!

Special notes regarding custom tuning parameters

The DDC unit has been carefully tested and calibrated to provide a complete engineered performance ride. Should you wish to make adjustments, all three of the below tuning factors will revise the overall fork performance.

- Main spring rates, spring preload and oil height will be the most common factors to adjust to suit special needs. The recommended spring rates from Cogent Dynamics are considered a mid-range standard and some customers may choose to make alternate selections/adjustments.

- Spring preload effects the front fork sag and the normal range of preload will be between 4mm – 15mm. Front sag should be near 30% of available fork travel. Stock travel for the KLR is approximately 200.7mm (7.9”).

- The recommended 130mm oil height gives a good mid-range air column in the forks with an excellent progressive feel for most dual-sport riding. Less air column (higher oil level) will add bottoming resistance and provide a firmer ride feel. A lower level will provide a more linear wheel rate and a plusher ride. Acceptable range of oil level is 150-115mm.

Some customers may find that they have differing preferences and choose to experiment with variations of damping settings. The DDC system allows for wide latitude of adjustability (“revalving”) where differing damping levels are desired.

Should you wish to revise the valving in your DDC, kits are available through Cogent Dynamics. Available options include: plush ride shim spindles, compression shim stack and a rebound spring kit. A full DDC tuning kit including all three of those items is available as the Pro-Tune Kit. Call for pricing and availability.