- Home

- Sale!

- Shop

- Featured

- Featured Products

-

DDC (Drop in Damper Cartridge) for the Yamaha TW200

0 out of 5$232.95

DDC (Drop in Damper Cartridge) for the Yamaha TW200

0 out of 5$232.95 -

Complete DDC kit for the Yamaha TW200

0 out of 5$379.95

Complete DDC kit for the Yamaha TW200

0 out of 5$379.95 -

Kawasaki KLR650 Adjustable Fork Caps Gen One 1987-2007

0 out of 5$208.95

Kawasaki KLR650 Adjustable Fork Caps Gen One 1987-2007

0 out of 5$208.95

-

- Featured Products

- About

- Service

- Bikes

- Resources

- Contact

Motorcycle Rear Shock Adjustment

Cogent Dynamics rear shocks are custom built for each customer and are delivered with settings which are excellent for most circumstances yet are designed with flexible adjustability so riders can set their suspension to best suit their changing needs. Some models of shocks will have different adjustment options. This page outlines the common adjusters that may be applicable to your shock including spring preload, rebound damping and compression damping.

Spring Preload Adjustment

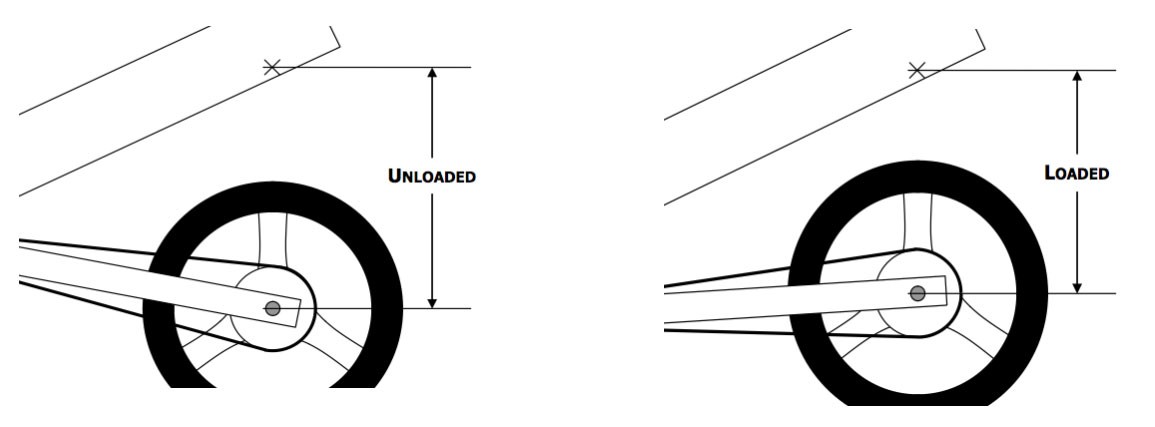

Spring preload refers to the amount a motorcycle suspension spring is compressed when installed on a fully extended shock (under no load). Changing a rear shock spring preload will change the motorcycles rear sag. Rear sag is the measure of change in rear ride height when comparing a fully extended suspension to a loaded suspension. Typically loaded and unloaded sag are considered (sometimes called “laden” and “unladen” sag). The reference measurement is the fully-extended suspension (as with the motorcycle wheel off the ground).

Performance of the rear suspension is typically best when the loaded sag is about 1/3 the available travel. Adjust this sag by increasing or decreasing the preload on the spring by rotating the threaded spring support on the shock Spring Preload Adjuster. Increasing or decreasing the amount of preload will not change the spring’s stiffness, it will only bring the rear of the bike up or down within its travel. It is important that the rear damper can respond to dips and bumps without excessive topping or bottoming of the damper. The sag recommendation is a guideline and experimenting with settings +/- 10mm from the suggested optimum settings may be advantageous to some riders.

To adjust the spring preload adjuster using the supplied pin wrench, be sure the wrench is fully inserted into the holes provided (drilled in a radial pattern) around the OD of the threaded spring preload adjuster. Supporting the rear of your bike on a center stand or lifting up on the rear helps reduce the spring load and the turning of the spring preload adjuster will require less force. The spring preload adjuster is fitted to the shock using normal right hand threads and reducing the installed length of the spring INCREASES the preload, raising the rear of the bike.

To adjust the spring preload adjuster using the supplied pin wrench, be sure the wrench is fully inserted into the holes provided (drilled in a radial pattern) around the OD of the threaded spring preload adjuster. Supporting the rear of your bike on a center stand or lifting up on the rear helps reduce the spring load and the turning of the spring preload adjuster will require less force. The spring preload adjuster is fitted to the shock using normal right hand threads and reducing the installed length of the spring INCREASES the preload, raising the rear of the bike.

At the time of construction, the damping adjuster was set at a recommended starting point for each customer and tested on the Cogent Dynamics damper dynamometer. Please feel free to experiment with different settings of spring preload but DO NOT make adjustments in either direction more than five revolutions of the spring preload adjuster as excessive or insufficient spring preload may occur, damaging the shock or motorcycle. When compensating for significant load changes such as heavy luggage, be sure to return to the normal setting after load is removed. Excessive preload can damage your shock.

Some shocks may be equipped with a Remote Preload Adjuster in place of the threaded spring preload adjuster. With the Remote Preload Adjuster, an adjustment knob is located in an easy to reach place on the bike and spring preload changes are made by twisting the knob in place of turning the threaded preload adjuster.

The Remote Preload Adjuster option gives a spring preload range of approximately 10mm of spring preload range which is the equivalent of about 6.5 turns of the threaded preload adjuster.

Rebound Damping Adjustment

Rebound damping is the damping force absorbed by a shock which opposes suspension extension. Too little rebound damping force will cause a loose or disconnected feeling or, at the extreme, even instability of the motorcycle. Too much rebound will compromise traction, often causing the suspension to feel stiff due to the suspension “packing” or riding lower in the stroke.

Rebound damping is the damping force absorbed by a shock which opposes suspension extension. Too little rebound damping force will cause a loose or disconnected feeling or, at the extreme, even instability of the motorcycle. Too much rebound will compromise traction, often causing the suspension to feel stiff due to the suspension “packing” or riding lower in the stroke.

The damping of Cogent Dynamics shocks are controlled via an advanced piston design that provides a varying damping force that automatically adjusts to the velocity and frequency of the wheel travel. The shock is designed with user adjustability to allow the rider to make changes to best match the conditions.

A rebound adjuster knob is located on the lower portion of the shock just above the lower mounting clevis or eyelet. This adjustment knob controls an internal jet that allows “bleed” or a bypass of fluid within the damper piston. Turning this knob in the clockwise direction (looking at the knob from the shock’s end) will cause the shock to become firmer and cause the rebound to become slower. Turning this control in the counter-clockwise direction will cause the damper to become more compliant and the rebound to become faster.

There are approximately 30 or more “clicks” of total active adjustment available. It is very important to count the clicks from the fully closed position (fully clockwise). When closing the adjuster, you are contacting the adjuster needle into its seat and for that reason it is very important to not exert anymore force than needed to feel the closed condition.

We recommend you record all the setup changes you make to your damper assembly so you can keep track of your changes. It is also a good idea to keep notes relative to the changes that you perceive when riding.

Pro-Series Compression Damping Adjustment

Compression damping is the force absorbed by a shock that opposes the compression or bump movement of the suspension. Excessive compression force causes a firm feel and keeps the suspension higher in its stroke on bumpy surfaces. Cogent Dynamics offers the Mojave Pro-Series shock that is simply one of the very best shocks available. The Pro-Series compression control canister adds a super high-tech piggyback or hose-mounted reservoir that includes an aluminum separator piston and a full 25mm, fully configurable “head valve” that provides an important level of compression damping control and adjustability to allow for a higher degree of performance, longevity, heat dissipation and adjustability.

Compression damping is the force absorbed by a shock that opposes the compression or bump movement of the suspension. Excessive compression force causes a firm feel and keeps the suspension higher in its stroke on bumpy surfaces. Cogent Dynamics offers the Mojave Pro-Series shock that is simply one of the very best shocks available. The Pro-Series compression control canister adds a super high-tech piggyback or hose-mounted reservoir that includes an aluminum separator piston and a full 25mm, fully configurable “head valve” that provides an important level of compression damping control and adjustability to allow for a higher degree of performance, longevity, heat dissipation and adjustability.

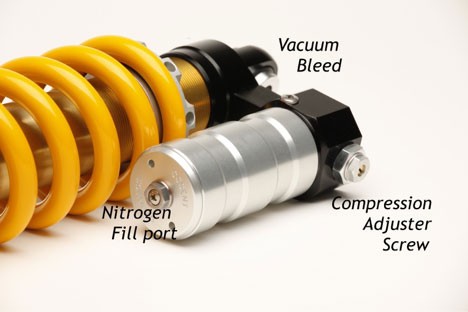

With regard to operation, the Pro-series shock shares the same features as the standard Cogent mono-tube shocks; however, the user has an option of adjusting the compression of the shock independently of the main “rebound” adjuster at the bottom of the shock. The compression adjuster is attached to the reservoir and is located either on the side or top of the reservoir, depending on your shocks configuration. To change the compression setting, simply use a flat-blade screwdriver to rotate the brass-colored screw. The standard setting is 10 “dots” out from fully clockwise. The dots are provided as a reference only and smaller changes than the space between reference dots are possible. The range of operation is from fully closed to fully open. Fully closed (clockwise) is the full stiff setting on compression and fully out (counter-clockwise) is the softest setting. Keep in mind, this adjuster serves as a “trim” adjustment for the internal valving of the 25mm auxiliary compression circuit located within the reservoir. This means that there is a quite wide range of adjustability but full soft still generates compression force and fully stiff is not an infinite amount of compression force.

The auxiliary valve in the reservoir produces a percentage of the total compression force that the shock makes and in doing so, distributes heat outside of the main damper body as well as providing better pressure balance within the unit. The reservoir allows for additional oil and gas capacity within the shock, aiding in heat dissipation and unit longevity.

There are other screws and fittings on the reservoir which are intended for assembly and service purposes only and should not be removed or turned by the user. The hex fittings around the brass-colored slotted adjuster is used to assemble the gland to the reservoir and should not be removed or turned, as high pressure oil could escape. There are two Phillips screw head port covers on the reservoir, with one being for the introduction and removal of the high pressure gas charge during assembly and servicing and the other is used to vacuum bleed and fill the shock during manufacturing.